#Sustainability

Suominen is offering a wide range of sustainable nonwovens

"Suominen’s vision is to be the frontrunner for nonwovens innovation and sustainability. We want to do our share in addressing the most topical global environmental concerns of our time, including scarcity of resources, climate change and marine plastic pollution. By constantly developing new and innovative solutions with a reduced environmental impact, we are able to provide a wide range of sustainable nonwovens for our customers", the company recently announced.

Innovation and sustainability are certainly nothing new for Suominen. Already ten years ago they launched the compostable and biodegradable BIOLACE® family of products produced solely from renewable raw materials. Since then, they have further developed and expanded their sustainable offering; the comprehensive Sustainable Product Portfolio was created in 2018.

Sustainability categories for Suominen’s nonwovens

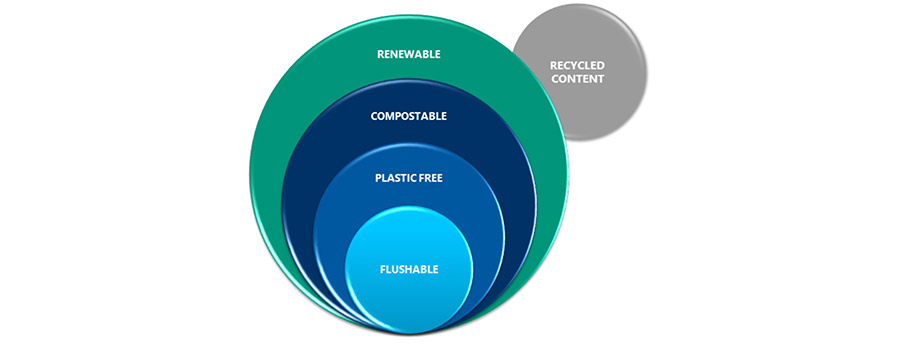

Suominen’s Sustainable Product Portfolio consists of products made from renewable, recycled and/or plastic-free raw materials as well as compostable and totally dispersible nonwovens. By offering solutions in these different sustainability categories, they can meet the varying sustainability-related needs of customers and end uses.

The sustainability categories

- Recycled content means that the nonwoven contains at least 15% of recycled fibers, such as recycled post-consumer polyester, polypropylene or post-industrial cotton fibers.

- Renewable means that all the raw materials used are from plant-based sources. We offer nonwovens made from a wide variety of renewable fibers, from biobased plastics to natural fibers.

- Compostable nonwovens are produced by using fibers from renewable resources that are compostable in industrial composting process as defined by international compostability standards.

- Plastic-free nonwovens contain raw materials made of biodegradable fibers of a natural origin, such as viscose, pulp and cotton.

- Flushable products are biodegradable and dispersible in water and comply with or exceed the latest industry flushability standards.

"From our Sustainable Product Portfolio, our customers can choose the sustainability category that is most relevant to them and then decide which of the products in the category are most suitable for their end products. At the same time, we also have a number of sustainable nonwoven alternatives available for various end uses, including baby, household, hygiene, medical, personal care and workplace", the company announced.