#INDIA ITME 2022

Loepfe will present leading products at ITME INDIA 2022

Market leading YarnMaster clearers and WeftMaster sensors

Loepfe (Hall H14 / Booth A2B1) will showcase the market leading YarnMaster PRISMA along with its well-established counterpart YarnMaster ZENIT+. With this dual offering, Loepfe uniquely leads both on technology and performance as well as on the proven reliability for all applications in winding. The latest field study results, which show the impressive cost savings achieved by PRISMA, will be the subject of many discussions. And Loepfe continues to report that promised customer orders are delivered as agreed ? a reliable partner at all times.

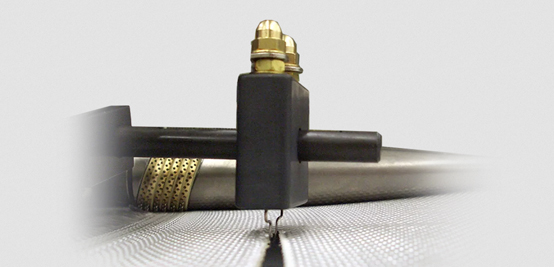

Loepfe has much to offer even beyond the spinning sector. For example, WeftMaster FALCON-i is placed in various processes from weaving and knitting, to processing different technical textile applications. FALCON-i is known for zero-defect manufacturing regardless of color, conductive materials, monofilament, or multifilament yarns, thus this sensor is successfully used in a wide variety of fields.

And WeftMaster SFB is commonly used in many Indian weaving mills for its efficiency-increasing effect. As the number of weft breaks can be substantially reduced, production is not interrupted - and obviously, weft break repair time is also saved.

Loepfe India – starting January 2023

As part of the strategy to move closer to the customers, and to offer even more effective local installation, training and troubleshooting services, Loepfe Brothers is founding a Loepfe India business unit. By fully integrating the teams of Masterline Technologies India in the three locations Coimbatore, Guntur and Vadodara, they are ensuring continuity while jump-starting their own local operations as Loepfe India, a unit of the local Vandewiele organization.

New partner for the weaving sector – Svan Texcon

To integrate more WeftMaster sensors in Indian weaving mills and support the local customers with a clear focus on the product range, Loepfe has started collaborating with Svan Texcon in India. The Svan Texcon team will serve the clients with need-based consultations and professional service for the WeftMaster product range.

Loepfe is looking forward to seeing many visitors there – hall 14 booth A2B1!