#Recycling / Circular Economy

Cooperations for creative and sustainable solutions

Innovation in a complex world comes from collaboration

Manifold collaborations for innovative smart poles

In addition to material properties and functionality, the focus is increasingly on design options. A current example of this is a smart pole designed for future mobility and smart cities – an intelligent pole with multiple functions that Covestro is presenting at the K 2022 plastics trade fair.

Smart poles must demonstrate stable performance even in harsh outdoor environments, while meeting high requirements for modern urban design, functionality and, not least, sustainable development trends. In addition to its own expertise and many years of experience, as well as a portfolio of suitable polycarbonate plastics and blends, Covestro therefore relies above all on intensive collaboration with technology and innovation partners in the development of such concepts, which include suppliers, customers, OEMs, start-ups, designers and universities.

This starts with product design: designs by students from Sweden's Umeå Design Institute were used to create the 5G small cell in the upper part of the smart pole. As part of a pilot project with this institute and Deutsche Telekom, Covestro investigated how a 5G network infrastructure could be implemented in an urban environment while taking aesthetic aspects into account. Polycarbonates are ideally suited for CMF (color, material, finish) design and enable interference-free transmission of high-frequency radio signals even in harsh weather conditions. To investigate the influence of material and CMF design under different conditions, Covestro operates state-of-the-art test facilities for a wide range of frequencies up to 50 GHz at its Asia-Pacific Innovation Center in Shanghai.

Together with the Umeå Design Institute, design concepts for electric charging stations for different usage scenarios have also been developed, one of which is the charging station design built into the base of the smart pole. Finally, as part of the modern urban landscape, the design of the smart pole must fit into the architectural and cultural context of the city in which it is installed. In addition to durability, the main focus here is on the weather resistance, flame retardancy, diverse light integration options and design freedom of the polycarbonates.

Circularity requires special partnerships

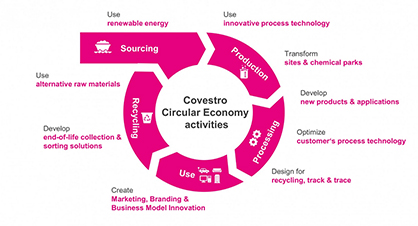

The value of such collaborations becomes even clearer when the complexity of the challenges increases: A circular world often requires the involvement of all partners along a value chain – industrial designers, raw material suppliers, plastics manufacturers, customers, disposers and recyclers. Only when all stakeholders are involved and work closely together can products be developed that can be recycled cleanly, reliably and affordably so that new products can be made from them.

Covestro works with partners from industry and science at all stages of a product cycle to find solutions for a more sustainable future. The exchange takes place with both established companies and start-ups. Covestro will be showcasing the results of these collaborations at the K 2022 plastics trade fair.