#Recycling / Circular Economy

SABIC creates the first certified circular polymers from advanced recycling of recovered ocean-bound plastic

- Thanks to a new collaboration with Malaysia-based plastic recycling company HHI, SABIC has produced the world’s first certified circular polymers through the advanced recycling of recovered mixed and used ocean-bound plastic

- First consumer products made using SABIC’s certified circular polyolefins from ocean-bound plastic will be announced over the coming months

- Project demonstrates SABIC and HHI’s ongoing commitment to drive towards a circular economy for plastics and helps prevent plastics entering our oceans and waterways

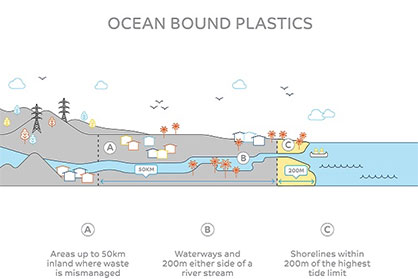

As well as helping to protect our oceans and waterways, the ocean-bound plastic collection helps to create value for local communities by increasing demand for recycled plastic across the industry. The material is recovered from ocean-feeding waterways and inland areas within a 50 kilometer radius of the ocean by HHI partners predominantly in Malaysia.

The recovered material is then sent to HHI, where they convert the used plastic into pyrolysis oil through an advanced recycling. The pyrolysis oil is then used by SABIC in their production process as an alternative to traditional fossil materials to make new certified circular polymers. The material has been certified under the Zero Plastic Oceans accreditation, and HHI is the first organisation to have received certification confirming the materials it recycles qualify as ocean-bound.

HHI created its own model to outline the steps required to facilitate the transition to a circular economy. The model has five stages which are to collect ocean-bound plastic through its extensive network; convert them into high-quality, manufacturable materials; collaborate with partners to create new products; provide customers with the platform to champion their use of more sustainable materials; and catalyse a generation of conscientious consumers who will opt for sustainable materials.

Abdullah Al-Otaibi, General Manager, ETP & Market Solutions at SABIC, said: “We are acutely aware of the challenges we face globally to stop plastic from becoming waste. Developing an entirely circular recycling system is a huge but necessary step we need to take together and will require all players across the value chain to collaborate. That’s why we’re committed to developing long-term solutions and working with new partners like HHI to significantly upscale the production of more sustainable materials, including those produced using recycled ocean-bound materials, for the benefit of our customers, society and the environment.”

Kian Seah, CEO at HHI, explains: “At HHI, our circular economy model helps to guide us in all of our endeavours, from business planning and collaborations with partners such as SABIC, to eco-initiatives, as we strive to protect our ocean and communities. We believe that we have the ability to work towards a cleaner future that views plastic as a valuable resource to keep within the value chain.

“We are incredibly proud of what we have achieved so far with SABIC, but also realise that we are early into our journey towards enabling a circular economy , and it is by no means a straightforward one. Our common spirit and passion has helped us overcome significant challenges to make this innovative process a reality and to ensure the reliability of technologies, quality of the end material and viability of the circular consumption model. We share a commitment to reshape the way we produce and recycle plastics and address environmetntal and societal challenges in a lasting, meaningful way.”

The circular polymers produced from ocean-bound plastic form part of SABIC’s TRUCIRCLE™ portfolio and services for circular innovations. Launched in 2019, SABIC’s TRUCIRCLE portfolio spans mechanically recycled products, certified circular products from advanced recycling of used plastic and certified renewables products from bio-based feedstock, as well as design for recyclability and closed loop recycling initiatives.