#Recycling / Circular Economy

Gama Recycle goes even greener with Oerlikon Neumag

Staple fiber plant is set to help a sustainable leader take global recycling to the next level

As one of the largest producers of regenerated yarn and fibers, you both recycle textiles and use R-PET bottle flakes in production. How did this develop, and why did you commit yourself to recycling?

We have been in business since 1997. From the very beginning, we produced recycled items. We gained a reputation for recycling textiles, as well as some plastics, so five years ago we even changed our name to Gama Recycle. To be honest, it was both environmentally and financially relevant at the time. There was a huge amount of plastic and textiles waiting to be reused. One of the most complicated aspects, though, was actually collecting all the materials.

What special considerations are required to produce regenerated yarns and fibers?

In the beginning, producing regenerated fibers and yarns was not a high priority for most people. Most countries and companies were not particularly sensitive to environmental issues. A lot of the cutting waste from the garment or textile industry was simply thrown away as trash or sent to be incinerated. It was not valuable for them to actually take care of these leftover materials.

As a result, we developed some ideas to turn these ‘unusable’ materials into regenerated fiber and yarn for several industrial use cases. We already have 18 patents for recycled products, machines, and equipment, with 10 more currently under review. Today, most garment manufacturers have started to sort and sell their leftover cutting materials, instead of simply throwing them into the garbage.

This is a huge improvement, because there were also only a few machine manufacturers on the market when we started recycling textiles, and most of the time we had to convert or modify our machines to make it suitable for recycling processes. Today, a lot of companies are focusing on recycling machines, and this has helped encourage a lot of growth in the whole industry as well.

What do you recycle, and which polymers are these materials made of?

We recycle pre-consumer cutting or industrial waste as well as postconsumer garments, PET bottles, PET trays, and other PET-based packaging materials or consumer products. We also have several patents for recycling previously used garments into recycled cotton and polyester fibers.

In what condition do you purchase your raw materials, and which steps of the process do you handle internally?

Sourcing is the most crucial and complicated part of our work. We purchase waste (our raw materials) from all over the world. We have several standards for raw materials, but unfortunately sometimes this does not match up with the specification of what you actually buy.

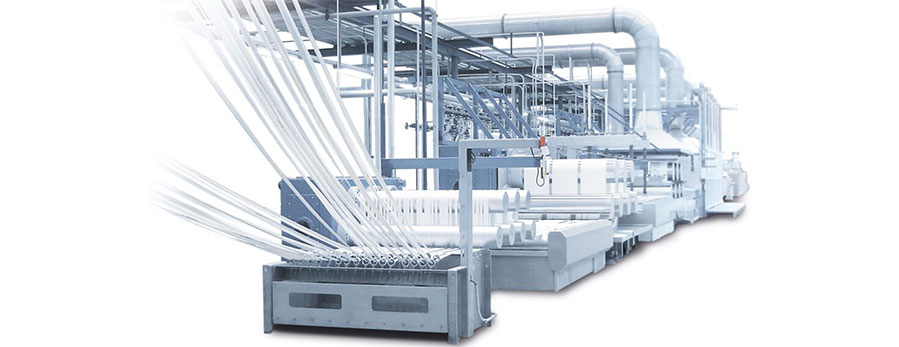

You will also use a staple fiber plant from Oerlikon Neumag in your production. What makes this plant technology so interesting for your process?

Recycled fibers have huge market potential. End-users are looking for environmentally friendly products, but they won’t compromise on the quality of the products they buy. This is why we prefer to use the Neumag fiber line. We are able to control the whole process in a very efficient way, with a consistently high quality of fiber as well as less production waste.

The preparation of recycling materials is a bit more complex. It seems that producing yarn and fiber from recycled materials is really profitable compared to virgin material. Or was your decision motivated more by idealism?

Yes, it is more profitable in most of cases – but also riskier and more complicated as well. You need a lot of know-how and experience, good machinery and equipment; otherwise, it will be a huge loss. While we do run a business, we are of course proud to do our part for sustainability and the environment by extending natural resources for future generations.

For example, we have developed a new patented fiber called CUPROCEL that is made of rPET polymer. Its touch, drape, stretch, recovery, etc., is not comparable to any other synthetic fiber. It is almost like cellulosic fibers such as modal or lyocell. We sell it as a fabric which is created with recycling processes. We even offer to buy cutting waste from our customers, as well as post-consumer garments. That is how we take sustainability into consideration. We believe this will help other people to follow suit.

What are your goals for the next three to five years? And what role does the Oerlikon Neumag plant play in your overall approach?

We will work up to a total of 300 tons of PET flake capacity per day, which will allow us, on a daily basis, to make 200 tons of recycled polyester fibers and 100 tons of PET chips for filament yarn and bottle-to- bottle (food-grade) applications. This is a great opportunity to have the Neumag line. With its impressive technology and capability, we will be able to achieve our goals more easily.