#Recycling / Circular Economy

Proven and new technologies for PET recycling and more

BB Engineering (BBE) will once again be appearing at K 2025 together with its parent company Barmag (a member of the Swiss Oerlikon Group) and its associated brands, showcasing its expertise in extrusion, filtration, and recycling. Under the motto “Barmag Recycling Technologies – Closing the Loop. Opening Potential,” the companies will place a clear focus on profitable sustainability at their joint booth 10H12 and provide information about a wide range of products and services.

Extrusion technologies – proven for decades

BBE's origins lie in extrusion: the company can look back on decades of experience and many thousands of extruders delivered. Its single-screw extruders are suitable for a wide range of polymers such as PP, PET, rPET, PA, and PE, and are particularly well suited for demanding applications in film production, synthetic fiber spinning, and high-quality PET recycling. With screw diameters ranging from 30 to 360 mm, the systems cover a wide processing spectrum and enable throughputs of 3 to 6,000 kg/h, depending on the material and process requirements. In addition to single-screw extruders, BBE also offers extrusion cascades for high output rates while meeting the highest quality requirements.

Efficient filtration for the purest melt qualities

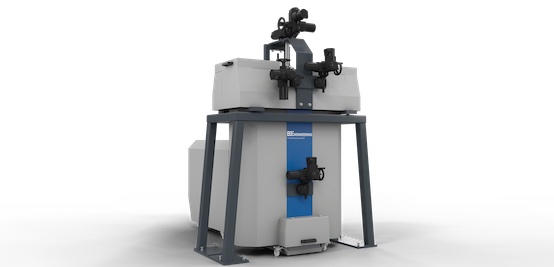

BBE perfectly complements its extrusion technology with a comprehensive range of melt filters – including the innovative COBRA filter, which sets new standards in continuous polymer filtration.

This powerful system features automatic valve switching and integrated inline intermediate cleaning. This equipment enables continuous, uninterrupted operation with consistently high filtration quality – a clear advantage, especially when processing recycled plastics with varying material properties. With a maximum filter area of 24 m² and a throughput of up to 4,000 kg per hour, the COBRA filter impresses with its high efficiency and stable process conditions.

Integrated recycling solutions for high-quality rPET melt For many years, BBE has been dedicated to developing high-performance technologies for plastics recycling. In addition to a broad portfolio of extruders, melt filters, and the VarioFil® R filament spinning system, which are designed for PET recycling, BBE offers VacuFil®, a fully integrated system for PET recycling via liquid-state polycondensation.

VacuFil® combines large-area, gentle melt filtration with precise IV control, thus ensuring consistently high quality of the rPET melt. The modular system concept allows flexible adaptation to different material qualities and areas of application in the recycling process. The capacity is 150-4,000 kg/h. The central component of the system is Visco+®, the liquid-state polycondensation unit for targeted viscosity adjustment. Continuous adjustment of the IV results in a homogeneous melt with optimal processing properties– ideal for high-quality end products in the fiber, film, or packaging industry.

Open House at the BBE Technical Center

At the BBE Technical Center in Remscheid, visitors can experience the entire product portfolio live, thanks to its proximity to the Düsseldorf Exhibition Center. Here, BBE is hosting an open house event on two days of the K show, where PET waste is recycled on the test facilities and spun directly into high-quality recycled yarn (POY). The new COBRA filter will also be on display here. The yarn produced is then further processed using BBE's JeTex® air-texturizing system with a new auto-doffing unit. (October 10 and 13, 2025, participation by individual invitation)