#ITMA Asia + CITME 2020

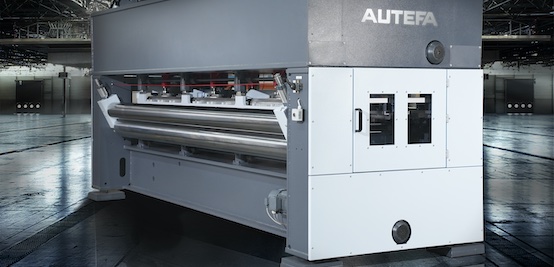

AUTEFA presents innovative solutions for the textile industry

The key advantages of the full range of the AUTEFA Solutions textile equipment portfolio will be explained, with a detailed focus on a number of specific innovations. Visitors will hear about the economic and technical benefits of AUTEFA as a systems supplier for full nonwovens lines in technology for carded-crosslapped needlepunching, aerodynamic web forming, spunlace production, and thermobonding.

In needlepunching, the company has developed monitoring and quality improvement techniques with its 3-level Closed Loop Control System. Here, a scanner evaluates weight distribution in the final product, while the control system adjusts the profile at the crosslapper and the card feed accordingly. The 3-level Closed Loop Control System also incorporates the WebMax Web Profile Control, which ensures that the fabric profile is regular in both directions. This results in excellent fabric uniformity, with consequent savings in materials and costs.

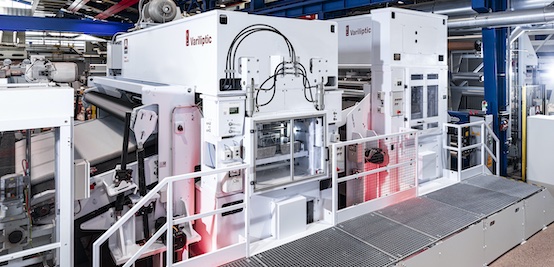

Optimized potential of fiber supply chain

As a global market leader in fully-automatic bale packing systems for staple fiber and tow, the company offers the entire range, from fiber transport to baler – as well as bale transport and warehouse storage of the pressed, wrapped and strapped bales. The Uni-Fork System from AUTEFA Solutions eliminates bottlenecks in fiber production logistics. With its flexible baling concept, AUTEFA Solutions sets the benchmark for fast-growing fiber line capacities.

Preferred option for cashmere woollen spinning

Natural fibres continue to grow in popularity for sports and leisure apparel, as well as next-to-skin clothing. For these applications, finer micron wools are required – which means spinners need to produce yarn using finer fiber and to even more exact specifications. AUTEFA Solutions machines deliver excellent quality outcomes in wool, alpaca, and cashmere. They can operate at precise speeds, ensuring consistency and evenness in both top and yarn production. Tops will typically be some 2-3mm longer, for the best-possible yarn quality. AUTEFA Solutions OCTIR-Dragon Multitrave worsted and semi-worsted cards guarantee high productivity without compromising the quality of the tops. The result is fibre fineness from 14.5-32 microns and fiber length from 20-150 mm.