Nonwovens / Technical Textiles

Porcher Industries and U.S. subsidiary BGF Industries to exhibit at CAMX 2018

Innovations will include new Dry Fibers for Aerospace & Automotive and the STELIA thermoplastic fuselage demonstrator, as well as composites solutions for the Industrial, Construction and Sports & Leisure sectors. Visitors will also be able to attend a technical paper presentation by one of Porcher Industries’ thermoplastic composites specialists.

High temperature thermoplastics for Design to Cost concept

Whilst showcasing a full range of composite and textile solutions, Porcher Industries will present a technical paper entitled “Design to Cost Concept for Thermoplastic Laminates”. Pierre-Yves Gandon (Thermoplastic Composites R&D Engineer) will speak about the development of two thermoplastic semi-products, suitable for the manufacturing of large structures for the Aeronautical sector and other markets such as Automotive and Industrial. The parameters explored for impregnation, consolidation and processability will be presented, along with the influence of these parameters and innovations on the mechanical, thermal and ageing properties of laminates. The presentation will take place at 9.30am, Thursday 18th October.

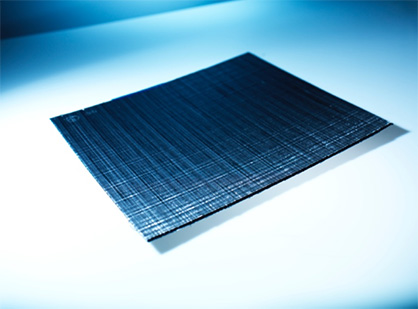

Dry Fibers provide new way of processing materials Out-Of-Autoclave

Porcher Industries and BGF will present a recently launched range of Dry Fiber products as a new way of processing materials out-of-autoclave for the Aerospace and Automotive sector. The carbon fiber with a wide range of binder interface is optimised for AFP-made preforms for thermoset resin infusion or injection, enabling high speed processing of complex shaped parts with outstanding buy-to-fly ratio.

STELIA Arches Box TP – Carbon/PEKK thermoplastic fuselage

Displayed on the Porcher Industries and BGF stand will be the STELIA Arches Box TP. Working with five partner companies, including Porcher Industries, STELIA developed this thermoplastic fuselage demonstrator to enable the first evaluation of this technology in a real industrial context. It features a Porcher Industries-developed organosheet from their PiPreg range of thermoplastic solutions as the optimal material for the frames, based on the initial specification. This project will be referenced in the Porcher Industries presentation at the conference on the final morning of the show.

Enhanced Thermoplastics for Automotive and Industrial OEM’s, plus High Performance Hybrid Reinforcements for Construction, and Lightweight Fabrics for Sports & Leisure.

For Automotive OEM’s, Porcher Industries offers a full range of products, from woven fabrics to PiPreg thermoplastic prepreg materials and pre-consolidated cured laminates, providing solutions for the most demanding applications in vehicle manufacturing, such as airbags, exhaust components and body parts.

Thermoplastic composites provide an array of options for Industrial applications, using an extensive range of technical textiles from dipped yarns, consolidated composites to scrims and woven fabrics. For example, in the replacement of metallic parts, thermoplastics offer superior chemical resistance without any additional surface treatment or coating. Other applications include electronic consumer goods and surgical instruments.

Glass, carbon and glass/carbon hybrids, including unidirectionals and plain weaves are high performing reinforcements for the Construction sector, and are particularly suited to the strengthening and repair of concrete columns, beams and floors. Textile solutions for thermal, acoustic and solar protection will also be showcased at the show.

Porcher Industries’ innovative approach and technical know-how has enabled them to develop products for the Sport & Leisure industry, particularly for paragliding and kite surfing, cycling, hiking and skiing. The lightweight reinforcements offer advantages such as water-resistance, high tear resistance, immersion control, with the Porcher Industries team continually working on next generation products.