#Weaving

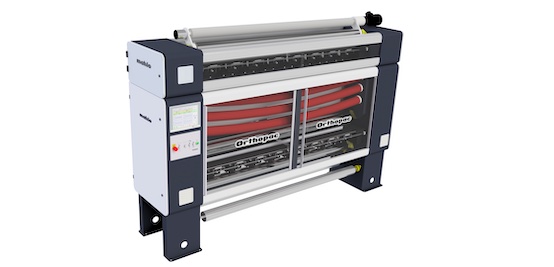

Mahlo's Patcontrol PCS-20

To ensure that customers receive the quality they want in patterned goods, textile manufacturers must adhere to the tightest tolerances in terms of parameters such as pattern repeat or pattern distortion. After all, nobody would accept distorted patterns in carpets, textile printing, woven goods and knitwear.

The Patcontrol PCS straightens bow and skew distortions in technical textiles just as reliably as in terry cloth, e.g. towels, printed clothing fabrics or flocked articles. Even goods that cannot be detected with conventional scanning systems, such as lace and rustle curtains or mesh fabrics used for example in sports shoes, do not pose a problem for pattern recognition. For years Mahlo has been providing reliable support for textile manufacturers with the Patcontrol PCS. The new version PCS-20 now facili- tates the production process even more.Some novelties will be introduced with the next generation of the pattern control system.

Camera and lighting technology further developed

The system uses camera technology to detect the position of the pattern and automat- ically and continuously determines the pattern repeat, measures the product width, and – together with a straightener – straightens the product distortion based on the print pattern.

New long-life LED lighting generates the maximum brightness on the market, thereby extending the scanning range for darker goods. Improved cameras allow brightness control by gain and exposure time. With the Generation 20 system, more than two cameras can also be connected per measuring point. This allows a higher resolution and an even more accurate result to be achieved. A Gigabit connection allows the transmission of large amounts of data. Using a mounting aid, the exact camera adjust- ment can be done easily and quickly. A compact interface box at the measuring point integrates the Patcontrol PCS-20 even more easily into the existing plant.

As with all current Mahlo systems, pattern recognition is also integrated into the mSmart digitisation concept. Users, machines and processes are networked with each other and meet all the requirements of Industry 4.0.

Area of application

- Straightening of curtain and lace fabric as well as repeat measurement and control of the feed roller

- Straightening of woven and tufted carpets before a coating process n Straightening of terry cloth (e.g. towels)

- Fine straightening of printed goods

- Report detection and sorting

- Continuous width measurement

- Logging of repeat and warp on carpets

- Residual distortion straightening of carpets at the stenter frame outlet n Special evaluations and measurements on technical textiles

Advantages of the new generationPatcontrol PCS-20 New camera technology

- Higher resolution – more than 2 cameras per measuring point possible n Gigabit connection

- Brightness control

- Easy camera adjustment

- CMOS technology New LED lighting

- Larger scanning range through maximum brightness on the market n Longer service life

Easy integration through compact interface box Current Windows 10 operating system

The Patcontrol PCS-20 ensures the textile manufacturer complete monitoring and log- ging of the actual product quality. The new generation of Patcontrol thus makes an important contribution to increasing quality, efficiency and profit. Its use brings compa- nies even closer to 100% 'Right First Time'.