#ITMA Asia + CITME 2020

Loepfe will present YarnMaster® PRISMA in Shanghai

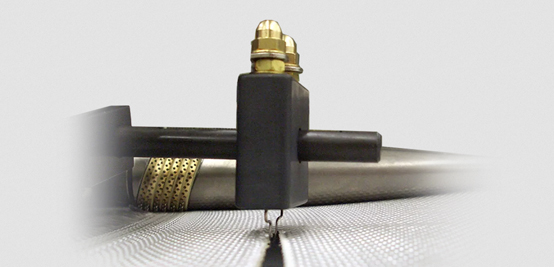

YarnMaster® PRISMA dazzles with its innovative use of four distinct sensor technologies – a unique blend that for the first time combines infrared optical, RGB optical, capacitive and triboelectric sensors and collaborating in perfect harmony, along with connectivity for the digital age. These elements not only allow the detection of previously invisible yarn faults and irregularities, but also the collection and analysis of data for effective online quality management through Loepfe’s MillMaster® TOP management cockpit.

Loepfe’s Head of Product & Solutions, Guido Wieland commented: “YarnMaster ZENIT+ is highly regarded as our workhorse and has been well-established over the years. And while our competitors are still using sensor technology that has been developed more than a decade ago, with YarnMaster® PRISMA we have clearly set the global benchmark for yarn clearing sensor technologies. Drawing on today’s smart technology, we have taken performance in its various applications to a whole new level. The whole team is excited to see the enthusiasm generated by the YarnMaster® PRISMA – and our motivation to deliver even more intelligent solutions is at an all-time high. Watch this space!”

Due to the prevailing Covid-19 travel restrictions, Loepfe will be represented at ITMA Asia 2021 by its partners C.N.T. - CIMACO Ltd. and Point Hope (Textile Machinery) Ltd., while Loepfe representatives will be available for ad-hoc conference calls at any time.