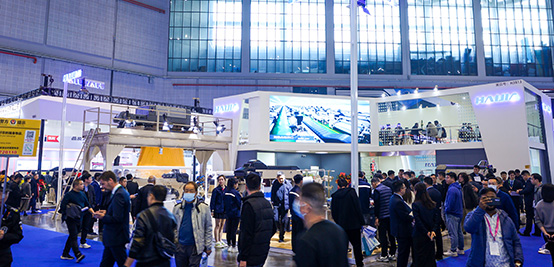

#ITMA Asia + CITME 2020

ITMA ASIA + CITME gears up for strong showcase in June 2021 despite current economic challenges

Show owners CEMATEX and Chinese partners, the Sub-Council of Textile Industry, CCPIT (CCPIT-Tex), China Textile Machinery Association (CTMA) and China Exhibition Centre Group Corporation (CIEC) have received applications from over 1,600 leading textile machinery manufacturers at the close of application period.

Although the deadline has passed, applications for space are still streaming in for the combined show, which will be held at the National Exhibition and Convention Centre (NECC), Shanghai from 12 to 16 June 2021.

Successful applicants will be receiving their certificate of admission and details of their booth space in December this year. The applicants, coupled with the strong support from various partners and industry associations, have given the combined show the clearest indication yet of a successful showing.

Mr Ernesto Maurer, President of CEMATEX, said: “We are very pleased to see so many companies booking with confidence as the industry moves forward to meet the growing demand of a post-pandemic economy. The Asian region continues to be a bright spot for businesses which are seeking new markets and growth opportunities in challenging times.”

The International Monetary Fund updated in June that in 2021 global growth is projected at 5.4 per cent. It also highlighted that economic growth will be strongest in emerging markets and developing economies, particularly in Asia which is expected to grow at 7.4 per cent.

Commented Mr Wang Shutian, Honorary President of China Textile Machinery Association (CTMA), “The positive economic growth is extremely good news for the industry. The pandemic has forced the industry to face unprecedented challenges. While a full recovery will take time, businesses around the world are already looking ahead to actively seek ways to prompt a market rebound.

“ITMA ASIA + CITME is a recognised brand and we are delighted that the industry continues to support our showcase. This is really a positive sign that industry players are cautiously optimistic about the future.”

Dilo Systems Gmbh, a leading company in the field of complete staple fibre nonwoven production lines, has been a regular ITMA ASIA + CITME participant. Identifying the potential in the combined show, Dr. Gunnar Hemmer, Sales and Marketing Director, said: “Next year’s combined show will be extremely important for all manufacturers as business has been badly affected by the pandemic. It will offer an excellent platform to help us reconnect with Asian buyers as the global economy is expected to improve. With an established track record, ITMA ASIA + CITME is in a strong position to support the overall recovery of the textile industry.”

Refreshed ITMA ASIA logo

As part of its efforts to unify the branding of its ITMA exhibition portfolio, CEMATEX has recently refreshed the design of its ITMA ASIA logo. Moving forward, the new image will be featured in the combined exhibition logo.

ITMA ASIA + CITME 2020 is organised by Beijing Textile Machinery International Exhibition Co Ltd and co-organised by ITMA Services. Japan Textile Machinery Association is a special partner of the show.

The last ITMA ASIA + CITME combined show in 2018 welcomed the participation of 1,733 exhibitors from 28 countries and economies and registered a visitorship of over 100,000 from 116 countries and regions.