#ITMA 2023

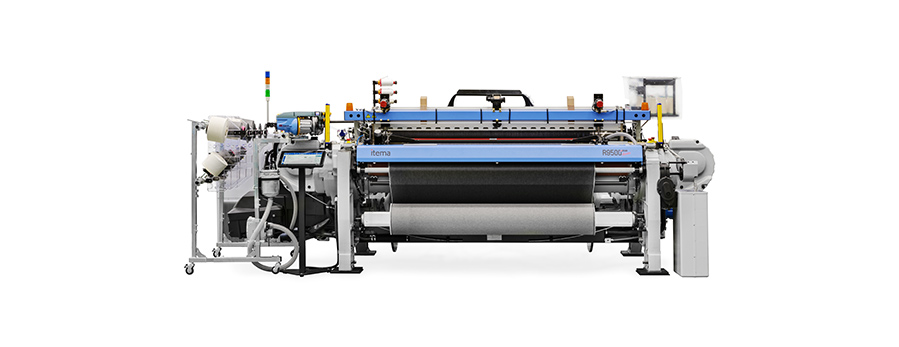

Itema Group at ITMA 2023: the new EVO range and a complete offering for the weaving industry

With a total of 12 Itema EVO weaving machines on show (7 in the Itema booth and 5 in the partners’ booth – Staübli, Van De Wiele, MEI, and Julibao), Itema confirms its attitude in exhibiting weaving machines running innovative, complex, and challenging fabrics to demonstrate its superior textile mastery. At ITMA 2023, Itema brings on stage sophisticated, diversified styles, designed in cooperation with leading textile companies – all Itema customers - such as ISKO, Mantero Seta, Drago Lanificio in Biella, Tessitura Marinoni, Frau Pérez Textiles, and Finsa Textil.

ITMA 2023 comes back in Milan, and Itema takes advantage of this prestigious stage to introduce its new EVO Weaving Range for the first time. The new EVO weaving range features significant innovations designed to raise the bar in terms of textile mastery, eco-efficiency, performance, and easy weaving.

Ugo Ghilardi, Itema Group CEO comments: “The new Itema EVO Weaving Range answers to concrete weavers’ needs. Our vision is to offer to our worldwide customers tangible innovations that, based on the most advanced engineering principles, can improve their productivity, competitiveness on the market, and user experience.”

In fact, the new Itema EVO Weaving Range includes:

• advanced solutions for the weft transfer to enhance versatility and machine performance

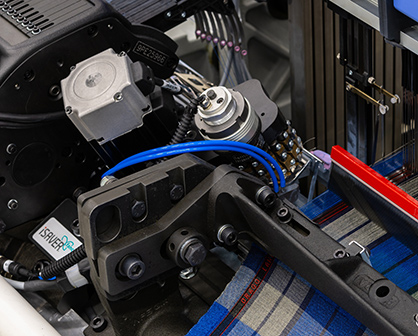

• the new iSAVER® range which, following its undisputed market success in denim weaving, is now available in up to 6 colors and for many more fabrics, thus significantly increasing the applications of sustainable weaving

• innovative digital software to enhance user experience and optimize textile production, such as iKNOWTM - the innovative tool that contains all the Itema textile experts' know-how collected on the field over the years - and MyWeaveTM the new, advanced mill monitoring system

• optimization of key machine components to further improve machine performance, ensure the best possible machine accessibility, and reach unbeatable reliability while preserving the renowned compactness of the Itema weaving machines, which provides weavers with valuable additional space in the weaving floor to install more looms

New digital solutions, such as the brand-new Itema Customer Portal HelloItema, further enriches the visitors’ experience.

Moreover, besides the unmissable weaving innovations on stage, the Itema Group booth hosts all the Group companies and solutions.?In fact, the Itema Group companies Lamiflex® and Schoch® with their advanced accessories for weaving machinery have dedicated corners in the Itema Group booth, and Itema and previous brands’ OEM spare parts are exhibited, including upgrade kits to optimize machine performance and retrofit latest Itema innovations on existing looms. Itemalab®, the Itema advanced innovation hub, has a special environment inside the booth to boost the innovation mission of Itema.

In addition, the booth hosts the range of nylon and polyester yarns from RadiciGroup, a leading group in the production of textile solutions for numerous markets such as apparel, furnishings, and automotive. In particular, RadiciGroup presents products with a reduced environmental impact, both from recycling and made with raw materials of bio origin.

Itema Group will welcome visitors with a product line-up designed to confirm and demonstrate its dedication to innovation and the Made in Italy excellence in the weaving sector.

Visit the Itema Group booth at ITMA 2023, in Hall 6 – B105.