#ITMA 2023

Savio winding and air-jet spinning innovations at ITMA 2023

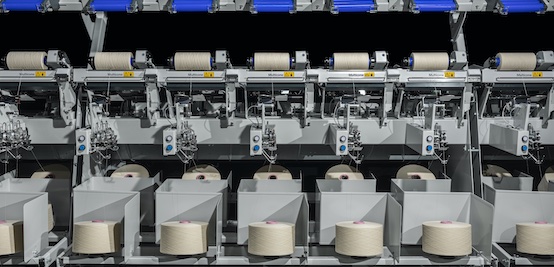

NEXT DESTINATION: PROXIMA Smartconer®

The new winding machine Proxima Smartconer® is setting the benchmark in Savio automatic winding.

Savio has combined the name Proxima with Smartconer®: it stands for a high-tech winding machine, capable of perfectly adapting to demands of Connectivity, Industry 4.0 and Industrial Internet of Things.

Thanks to the innovations, spinners will get a machine featuring high-tech capabilities, thanks to a design with a strong focus on the main benefits for customer’s competitive advantage: high productivity, low energy consumption, premium yarn quality, automation, and data connectivity.

Proxima Smartconer® has been designed with the foremost attention to the customer’s needs in the optimal utilization of a winding machine.

Investing in equipment that enables to work faster and reduces manual and repetitive tasks, can increase both efficiencies and overall productivity. The same applies to a new equipment that does more of what is needed, faster, safer, with better quality but with less waste, less maintenance and less resource usage.

The team at Savio is steadfast to provide textile solutions for spinning business growth with unsurpassed customer service, response time, and technical expertise.

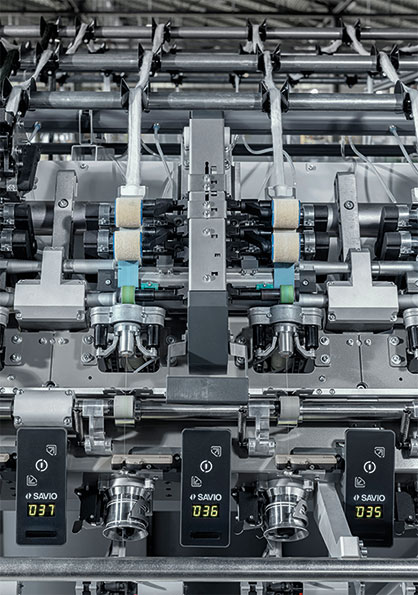

"WE SPIN DIFFERENT": LYBRA Smartspinner®

Savio's message is: "We spin different with a versatile and smart machine". The company's new air-jet spinning machine Lybra Smartspinner® has been developed with an original spinning technology to serve the customers in specific applications of textile production: knitting, home textiles, sunshades.

Air-jet spun yarn has a soft and smooth character, perfectly adapting to creating functional & fashionable fabrics. With LYBRA Smartspinner®, Savio wants to offer its customer a versatile, flexible, cost saving and easy-to-use machine. Air-jet spinning offers to yarn manufacturers the opportunity to produce yarn at high production rates and low processing costs.

One important technology of LYBRA Smartspinner® is the MULTI BLEND SYSTEM.

This onboarding system allows to use two separate slivers, instead of a pre-blended one, directly fed into the spinning unit; inside the spinning chamber, the fibres are mixed together producing a final yarn of same aspect and features as the standard one. Moreover, the system can modify the composition of the blend directly from the machine PC, without changing the feeding slivers. This allows a reduction in production costs and an optimization of the preparation lines. Savio can obtain different material blends but also different colour mixtures. This application will be highly appreciated especially for knitting and home textile applications, producing melange knits and fabrics.