#ITMA 2019

Taking quality to the next level for tufters

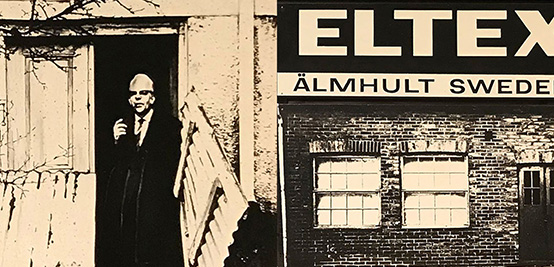

“Such companies are typically manufacturing very expensive carpets made in a myriad of patterns and if faults are allowed to occur they can be very expensive to mend,” says Brian Hicks, managing director of Eltex of Sweden, the developer of the technology. “If all goes to plan – and all the testing results are very exciting so far – we will be unveiling the latest version of the Eltex EYE at ITMA 2019 in Barcelona, Spain, from June 20-26th.”

The latest advanced tufting machines, he explains, put significant limitations on the space that is available for yarn fault detection systems, and the Eltex EYE is very comprehensive, with each yarn individually controlled for a 100% detection of every tufting yarn break and end out.

“Unlike scanning inspection systems, we are monitoring each individual yarn position in real time,” says Mr Hicks. “As a consequence, we have concentrated on the further miniaturisation of our sensors. Our sensors are usually fitted between the feed rollers and the needles and based on the well proven piezoelectric principle. Their special compact design already enables them to be fitted on machines with gauges as dense as a tenth of an inch.”

All of the data from the sensors is processed by a master control unit which provides stop and warning light indications to the extremely user-friendly operator terminal in response to any detected yarn fault.

Trans-Atlantic service

Eltex reports major gains with its first generation Eltex EYE in the carpet and artificial grass manufacturing sectors in recent years.

“We have been cementing our position in this industry over the past few years and I believe that the system we introduce at ITMA 2019 will take yarn fault detection to a whole new level of security and quality assurance for tufters,” Mr Hicks says.

The USA remains the world’s epicentre for carpet tufting and Eltex customers are served there from the company’s wholly-owned subsidiary in South Carolina. Western Europe, however, still has a strong manufacturing base, particularly in Belgium, Denmark, Germany, the Netherlands and the UK, while Turkey dominates in woven carpets.

With its research and development work primarily carried out at its headquarters in Osby, Sweden, the company’s manufacturing plant has been located at Templemore in Ireland since 1976, providing significant advantages in terms of high flexibility and logistical services to customers on both sides of the Atlantic.

Eltex is a member of TMAS – the textile machinery association of Sweden which will have a significant presence at ITMA 2019 in Barcelona.

“The innovations of Eltex solve customer problems in real time, with a direct impact on operational costs,” says TMAS Secretary General Therese Premler-Andersson. “The Eltex case perfectly illustrates the strong customer focus of Swedish textile machinery producers, combined with their long experience and drive to innovate. There will be many more innovations on show from our members at ITMA 2019.”

Eltex will be at stand B102, in Hall 4 at the Barcelona exhibition.