#ITM 2022

ITM in Istanbul: Saurer Spinning Solutions presents innovations in intelligent spinning

Saurer Autocard – create further value in the fibre preparation chain

The new Autocard’s higher carding area means 18% higher output and even cleaner sliver. It also features LED lights for intelligent operator guidance. It was developed to create further value in the fibre preparation chain. It offers the right solutions to prepare all kinds of fibres for the subsequent processes in the textile value chain. The right combination of blow room and carding machinery ensures excellent fibre utilisation and sliver quality, thus increasing the efficiency of the spinning process and improving the quality of yarn.

Autocoro – the most popular rotor-spinning machine in Turkey

Clever solutions for more productivity, flexibility, yarn quality and sustainability are the recipe for success for Saurer spinning machines. The automation solutions of the Autocoro rotor spinning machine and the Autoairo air spinning machine pave the way to more independence from the availability of personnel, more output and quality assurance and also reduce spinning and raw material costs.

The Autocoro has an outstanding market position. In just 10 years, Saurer installed one million of Autocoro spinning positions with individual drive technology. The Autocoro is the market and technology leader, revolutionised automatic rotor-spinning technology and opened the door to more productivity, flexibility and sustainability for numerous customers worldwide.

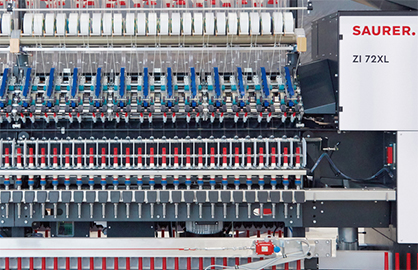

ZR 72XL and ZI 72XL – the global benchmarks for intelligent spinning

ZR 72XL/ZI 72XL are two highly productive ring- and compact-spinning machines. They set the global benchmarks for intelligent spinning, low energy consumption, user friendliness and flexible automation solutions. From the finest compact yarns for high-quality shirting fabrics to coarse denim effect yarns and recycled yarns – with their flexibility, the Saurer ring-spinning machines open up access to almost all applications. Equipped with the proven Optisuction and Twinsuction energy-saving modules, the ZR 72XL/ZI 72XL additionally impress with highlights such as Impact FX, Draftbox, Spinnfinity and Optispeed.??ZR 72XL/ZI 72XL, two all-rounders which, linked with any package winding machine, prove their efficiency on a daily basis and reduce labour and space requirements to a minimum.

Sun – Service Unlimited offers life cycle partnerships for all Saurer machines

Profitable, durable and sustainable: Saurer offers customers a lifelong partnership for their rotor- and ring-spinning mills. The company has been present in Turkey for years with its own Customer Service Centre in Kahramanmara? Saurer invites visitors to ITM to the Sun area at its booth: the company’s service experts will show them the latest offers for updates and upgrades, original parts and clever preventive services for their existing machinery. Visitors will also discover how they can also make older Autocoro and BD machines fit for the demanding processing of recycled fibres with profitable conversions and software upgrades. Saurer also offers free test versions for many Autocoro software upgrades.

See the full picture with Senses

Senses is Saurer’s IOT platform that allows customers to connect all Saurer and third-party machines in one system. The application increases overall product quality and productivity through detailed and transparent data monitoring across various production processes along the textile chain. In addition, Senses supports the user with important information to quickly find problem-solving solutions. Senses reduces textile mills’ labour costs by automatically collecting and analysing data – even for future use without loss of data.

Senses Elements are modular extensions of Senses to manage customers’ mill and widen the function range in the areas that are particularly important depending on a customer’s individual needs. Customers can easily purchase the Senses Elements via the Saurer Senses Software Shop.

Texparts – Introducing the new E-shape spindle with 17.5 mm wharve diameter

Eshape has a reduced wharve diameter. The double elastic spindle is based on CS 1 S, which has proven its worth over many decades. Outstanding running properties up to 30 000 rpm and about 4% energy saving are the key performance factors. Eshape combined with the best system for spinning without underwinding, Spinnfinity, is the perfect fit for automated and efficient ring spinning. Dirt-resistant, durable and lightweight – these are the qualities that enable Spinnfinity to reduce costs, increase productivity and improve ergonomics.

The Saurer team looks forward to answering all visitor questions at the ITM Booth 310A in Hall 3 from 14 to 18 June 2022.