#ITM 2022

Stäubli at ITM 2022 – Solutions delivering greater benefits

A world premiere for efficient Jacquard weaving

SX PRO Jacquard machine answers challenging market demands

The new Stäubli SX PRO responds to market demands for higher power efficiency and lower energy consumption. It incorporates all of the proven technology of the predecessor Stäubli Jacquard machines as well as several innovations to reduce energy consumption: low-friction design of the MX PRO module, power supply fully integrated into the machine itself, and a new ventilation system with optimized temperature monitoring. Equipped with up to 2,688 hooks, the SX PRO is perfectly adapted to the needs of the Turkish market, where terry cloth, apparel fabrics, tapestries, and upholstery fabrics are produced.

Visitors to the Stäubli booth can observe the new SX PRO Jacquard machine in combination with a Stäubli harness at a demonstration stand.

N4L narrow Jacquard machine enthuses weavers of luxury fabrics

The N4L narrow Jacquard machine adds value to premium fabrics by weaving the brand name or logo into selvedges, which also safeguards against counterfeiting. It was unveiled at ITMA 2019 and has since become firmly established in the market. Many customers have sent us highly enthusiastic comments about the machine, some praising the revolutionary positioning mechanism, as the machine is easy to place anywhere along the reed with no need for tools. It is perfectly compatible with all weaving machines because the design was informed by our longstanding partnerships with many major players in the weaving industry.

Frame-weaving solutions for high quality and efficiency

High-speed S1792 cam motion for air-jet weaving

Since its launch at ITMA 2019, the exceptional S1792 cam motion has made a name for itself around the world. With impressive speed and reliability, it squarely masters the two main challenges of air-jet weaving: quality and performance. This cam motion is available with a housing size of 10 lifting units. It is another convincing Stäubli solution that allows weavers to stay at the forefront of their demanding markets.

S3000 / S3200 electronic rotary dobby family

The rotary dobby is a revolutionary machine invented by Stäubli many decades ago, and Stäubli has been continuously developing it further. The third generation of electronic rotary dobbies, the S3000 / S3200 electronic rotary dobby family, is an evolutionary design. It incorporates the unique Stäubli locking system, which provides enhanced security for the selection of the heald frames, allowing higher running speeds and superior reliability. This latest generation of electronic rotary dobbies offers astounding benefits to weavers.

Newly developed transmissions with lower maintenance

The transmission is a vital link in the frame-weaving installation, handling a great many loads and forces. Dedicated to continuous improvement, Stäubli has further developed its range of transmissions and now offers the e32/33 for low-mounted and the de82/83 for top-mounted dobbies. With sealed and patterned bearings, these new transmissions reduce the need for maintenance and enhance the performance of the overall installation.

An S3060 dobby for rapier and air-jet weaving machines can be seen at the booth in operation with frames as well as an S3260 model with 16 frames in combination with latest maintenance-free transmission.

Enhanced warp quality through automation in weaving preparation

Active Warp Control (AWC) on SAFIR drawing in machines

The renowned SAFIR automatic drawing-in machines make it possible to shorten workflows, resulting in cost savings and expanding the variety of application possibilities. Equipped with state-of the art Stäubli technology, the so-called Active Warp Control (AWC), the SAFIR drawing-in machines feature capabilities such as colour recognition or yarn repeat management. Even warps with multiple colours and without a 1:1 lease can be drawn in, with no error or loss of productivity. The final result is a perfectly drawn-in weaving harness ready for the downstream weaving process. Visitors to ITM 2022 can witness for themselves the impressive efficiency of automatic drawing in with the SAFIR S60 model, dedicated to the needs of cotton fabric mills whose main applications are denim, bed linen, and plain fabrics for printing.

Stäubli is exhibiting the SAFIR S60 (2.3 m wide model) drawing in a multi-coloured (5 colours) cotton warp sheet. The warp sheet is 1,750 mm wide and comprised of 8,650 ends (yarn count Nm 135) (Ne 9). The yarn is being drawn into 8 heald frames including healds made of steel with J-shaped end loops, drop wires, and reed.

TIEPRO warp-tying machine – the new ‘must have’ Stäubli solution

Another crucial process in many weaving mills is warp tying. Stäubli is presenting the TIEPRO warp tying machine together with TPF3B-10 warp tying frame. This machine offers unique features supporting easy start up and processing of the warp to be tied. New staff can easily learn how to run the machine as the screen guides the operator. A standalone advantage of the TIEPRO tying machine is that if a double end is detected, the machine with its exclusive auto-reverse function automatically reverses and redoes that yarn separation step. This process takes place before the yarn is cut. The machine does not require an oil bath and maintains high availability in the mill.

Being demonstrated at the booth is the warp-tying process with a unicoloured cotton warp sheet, yarn count Nm 135.

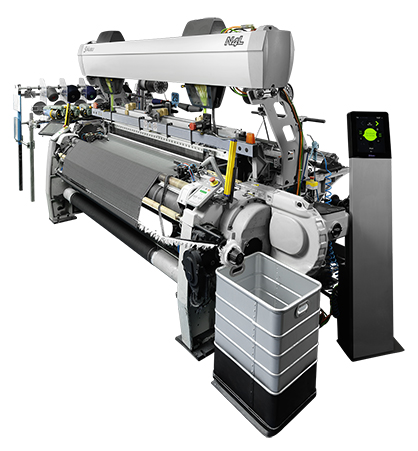

Carpet-weaving systems and design technologies for any type of carpet

Stäubli recently launched the ALPHA 560 UNIVERSAL carpet weaving machine. This new weaving system offers many redesigned features to deliver increased productivity while handling a wide range of carpet sizes and varieties. The enormous flexibility of this machine is supported by its real 3-position LX2493 Jacquard machine, featuring the proven M6T module. In combination with the Multi Weft Selector (up to 6+6), impressive designs for carpets with weaving widths up to 5.3 metres can be woven.

Latest carpet samples woven on the ALPHA 560 UNIVERSAL can be seen at the booth.