#Dyeing, Drying, Finishing

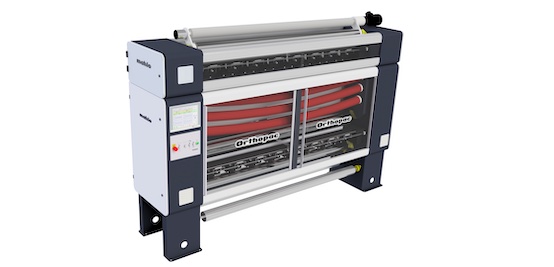

Revolutionizing textile production: Thomas Höpfl discusses Mahlo's cutting-edge Orthopac RXVMC-20

Question: Thomas, thank you for taking the time to speak with us on the topic of optimizing textile production. Let's dive right in. At the ITMA Europe last year, Mahlo has presented the prototype of its latest product development Orthopac RXVMC-20. Now the first machine is installed at a customer. Can you give us an overview of the new straightening concept?

Thomas Höpfl: Good morning, and thank you for having me. The Orthopac RXVMC-20 is our latest innovation designed specifically for processing textiles with high distortion dynamics, particularly in the knitwear sector. It’s a sophisticated system that combines control and regulation to offer maximum control over the straightening process.

Q: What makes the Orthopac RXVMC-20 stand out from conventional straightening systems?

T.H.: The key differentiator is its ability to handle textiles with highly variable distortions effectively. Traditional methods struggle with the inconsistencies often found in knitted fabrics, which can be influenced by numerous factors such as the sewing together of short pieces and the type of knitted fabric. Our system uses independently controllable and adjustable straightening modules that provide a high level of precision and control, thanks to advanced scanning and evaluation electronics.

Q: Can you elaborate on how the system works?

T.H.: Certainly. The Orthopac RXVMC-20 consists of two straightening modules, each individually controllable and driven. Distortion sensors at the infeed of the first module detect any fluctuations before they reach the straightening rollers. These rollers are then adjusted using stepless hydraulic or electric drives. A self-optimizing, AI-enhanced control algorithm ensures a highly precise and fast response to these detected distortions. Additionally, there is another distortion detection system at the outlet of the second module that catches any residual distortion, ensuring it is corrected.

Q: That sounds impressive. How does this system benefit textile companies in practical terms?

T.H.: The most significant benefit is the ability to meet high-quality standards regarding permissible residual distortion, which is crucial in the textile industry today. This system not only improves the quality of the finished product but also reduces waste and increases efficiency. For instance, lower profits due to non-compliance with residual distortion values are now avoidable. This system ensures that companies can maintain consistent quality, thereby increasing their competitiveness in the market.

Q: Could you share an example of a company that has implemented this system and the results they have seen?

T.H.: Of course. Tintoria Finissaggio 2000, a renowned textile finishing company, recently installed the Orthopac RXVMC-20. They specialize in a wide range of finishing treatments for various fabrics. After equipping their new stenter with our system, they saw significant improvements in quality and efficiency within just a few months. The owners, Dino Masso and Marco Bardelle, mentioned that their expectations were far exceeded by the results.

Q: That's quite an endorsement. What was the feedback from Tintoria Finissaggio 2000 specifically?

T.H.: They were very pleased with the precision and rapid response of the system. Dino Masso and Marco Bardelle highlighted that their high hopes for the Orthopac RXVMC-20 were more than met. They experienced a substantial enhancement in their production process, which is a testament to the system's effectiveness and reliability.

Q: It seems like the Orthopac RXVMC-20 is set to make a significant impact in the textile industry. What are Mahlo's plans for the future with this technology?

T.H.: We are continuously working on innovations to further refine our systems. The success of the Orthopac RXVMC-20 has encouraged us to explore new ways to integrate AI and advanced control algorithms into our products. Our goal is to offer even more efficient and precise solutions to meet the evolving needs of the textile industry.

Q: Thank you, Thomas. It's been great learning about the Orthopac RXVMC-20 and Mahlo's contributions to textile manufacturing. We look forward to seeing how this technology evolves.

T.H.: Thank you for the opportunity to share our advancements. We’re excited about the future and committed to continuing our role as a leader in textile process control systems.