#Dyeing, Drying, Finishing

Symposium in Indonesia

In his presentation, Mahlo's Head of Sales Thomas Höpfl explained how data-driven production can be the answer to today's challenges in textile finishing. "Against the backdrop of the current rise in energy prices, online quality control in textile production is suddenly more important than ever before," said the experienced textile expert, describing the current situation. "The uncertainty on the market is forcing manufacturing companies to increase the flexibility and efficiency of their production and minimise manufacturing costs by using fewer resources."

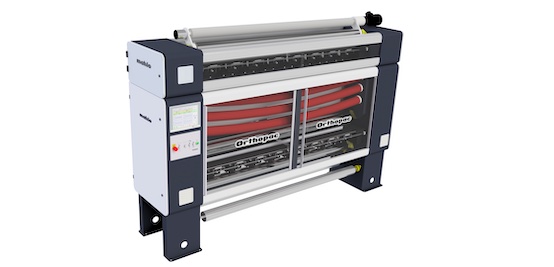

Leading industrial companies are thinking ahead, producing sustainably before they are forced to and introducing automated processes and networked high-tech devices to analyse live data. The key points are the correct collection, analysis and preparation of the right data as well as the seamless transition of data flows between machines, company divisions and to other companies such as customers or suppliers. In his presentation, Höpfl used the example of a modern stenter frame to show how modern and I4.0-compliant quality assurance systems from Mahlo are structured. The broad portfolio of intelligent modules for exhaust air humidity control, residual humidity control, heating set control, line density measurement and control and, last but not least, distortion correction was presented.

"The measured values are processed directly in the sensors' real-time processors." The finished measurement data is visualised internally in an intuitive Human Machine Interface (HMI) or transferred to an external network via interfaces. The implemented automatic control algorithms interact directly with the corresponding actuators of the stenter frame and reduce the deviation from the target, resulting in a more uniform end product. This enables optimised setpoint specifications and, in addition to improved product quality, leads to significant savings in raw materials and energy costs. Process reliability and production throughput also increase.