#Innovate 2021

Mahlo at the virtual Innovative Textile and Apparel Show

"Solutions for Textile Finishing, Nonwovens and more": this is the all-embracing motto at the Mahlo stand, which will take visitors into the world of measuring and control technology of the highest quality standards.

Thread-straight goods and optimised processes

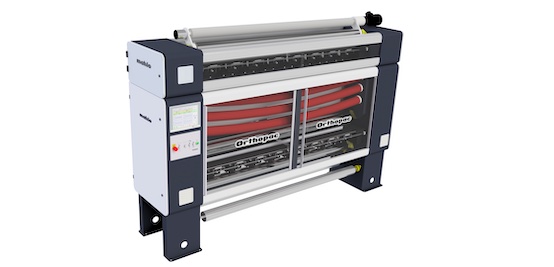

In the textile industry, Mahlo is synonymous with high-quality automatic weft straighteners. The experts' recipe for success is decades of experience paired with the latest technological developments. Whether roller or needle straighteners, whether for the finest textiles or heavy fabrics - interested parties can find out about the right equipment for their specific requirements.

Solutions for technical textiles and nonwovens

Support in the production process is also available for technical textiles and nonwovens. The focus here is on the Qualiscan QMS quality measurement system.

The modularly designed system, which consists of sensors and measuring frames, measures, logs and controls critical parameters such as basis weight, moisture or layer thickness across the entire fabric width. Depending on the application and task, different measuring methods are used for this purpose.

Thanks to this broad portfolio, Mahlo offers customised solutions for almost all requirements.