#INDEX 20

EL.NET – Complete networking

E+L web guiders are I 4.0-ready

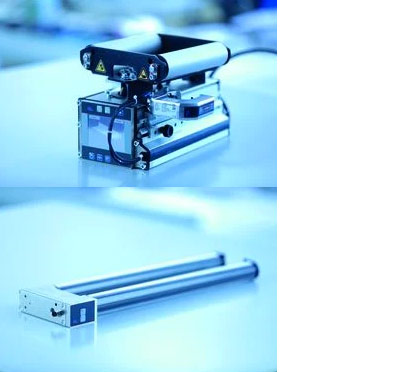

The DRB pivoting frame series offers all the benefits of networking, from brushless small web guiders through to large pivoting frame systems. All the components of the DRB series are networked using Ethernet and form their own network.

Besides the rapid and transparent data exchange within the system, this data is now available for Industry 4.0 applications. In principle, Erhardt+Leimer has let itself be guided by the open architecture and offers this benefit irrespective of the hardware and software. This means that any user with standard terminals, such as a PC, tablet or even smartphone, can access the system with a browser, make settings or operate it in a simple way. The precondition is simply access via the machine or the Intranet of the user. In addition, this technology now offers real Plug & Play functionality, which E+L will present at its stand.

Wide band sensor for the evaluation of up to four edges

The networking concept is rounded off with the FR 61 infrared wide band sensor, which is available with a fork length of up to 480 mm and allows itself to be equally seamlessly integrated into the described system architecture.

Web tension measurement and control

The PA 62 web tension measuring amplifier and the DC 62 web tension controller can of course be networked with the machine in the same way as the products named above, thus closing the circle of complete networking. The benefits for the customer: a two-channel measuring amplifier, LCD display for displaying the actual web tension value, a trend curve or the individual values for the left and right side of the web. Alarm functions on exceeding limit values, which can be configured individually, are included, too.

Erhardt+Leimer is at stand 4443.