#Domotex

The Future of BCF Technology

„The RoTac tangle unit has been the effective solution for the single-end BCF plant Sytec One since 2012. In the meantime, practically all Sytec Ones are sold with the RoTac. However in order to use this technology for our flagship S+, a considerable amount of detailed work was necessary“, stated Mathias Stündl, Head of BCF Development at Oerlikon Neumag.

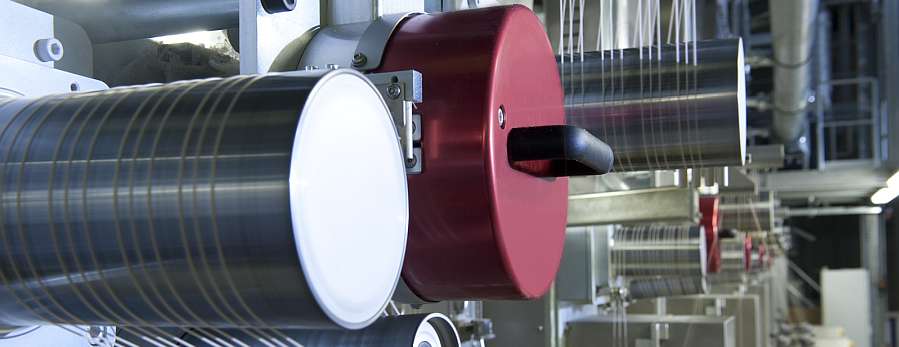

RoTac3: A further plus for the S+

The new RoTac3 is perfectly tuned for the 3-end BCF plant S+. In comparison to conventional tangle units, the RoTac technology forms the tangle knots with a pulsating instead of a continuous air current. The core element of the RoTac is a rotating nozzle jacket which has several holes with a corresponding spacing according to the required number of knots. If a hole is positioned over the compressed air opening, an air blast is released and tangles the yarn. Therefore compressed air is only consumed if a tangle knot is to be formed. The necessary volume flow and therefore the energy consumption are significantly reduced. In comparison to conventional tangle units, the compressed air consumption is reduced by up to 50%. Therefore the RoTac3 has been granted the e-save label for particularly energy-efficient and eco-friendly technologies.

This principle enables the RoTac³ to generate tangle knots with defined distances and controllable strengths. Tangle dropouts are reduced and downstreaming performance improved. A very gentle yarn treatment reduces the yarn tension. The resulting, better process stability is very beneficial for future trends such as fine deniers and demanding polymers. RoTac3 is immediately available for the BCF plant S+ and can be retrofitted in already existing S+ plants.

Whereas the S+ is convincing for commercial applications, the Sytec One is particularly suitable for the demanding production processes because of the one-end application. With the S+ and Sytec One, we are excellently positioned on the global BCF market and can practically fulfill nearly all the customers’ requests “, ensures Martin Rademacher, Sales Director BCF.

Interested professional visitors can experience the production platform of both plants together with the RoTac3 literally live in a three-dimensional Virtual Reality Show on Oerlikon Neumag’s booth at the Domotex. The interactive presentation gives the observer a completely new perspective on sequences, machines and plants.

Premiere: 10 Years BCF Technology Symposium

It is the first time for Oerlikon Neumag’s BCF Technology Symposium to take place in Hanover. It will be a special event, as it is the 10th anniversary to be celebrated on Monday, 19.01.2015. This annual forum previously always took place as a one-day event at the company’s headquarters in Neumünster, and presented fascinating market subjects such as recycling or the growing significance of PET, to a professional audience from all over the world.

Pic: The rotating tangle unit RoTac3