#Digital Printing

Kornit Digital rewrites the rules for fashion and textiles at Kornit Fashion Week Tel Aviv 2022

- Hundreds of designers, brands, creators, e-com platforms, manufacturers, and virtual fashion pioneers expected to attend VIP events at Kornit’s headquarters, R&D and production centers, and in major venues of Tel Aviv

- Kornit will unveil future technologies and solutions, including the revolutionary Kornit Apollo fully-digital mass production direct-to-garment (DTG) platform – considered a future game-changer for the mainstream mass production of fashion and apparel, a multi-billion-dollar market opportunity – constrained today by antiquated, analog, and polluting methods of production

- Mass production of textile, traditionally off-shored, is going through an accelerated shift to near-shore production, significantly shorter production runs, lean-to-no inventory risk, and unlimited creativity and flexibility for designers and creators – all possible with Kornit’s new solution for mass production

- Kornit will also unveil its Kornit Atlas MAX Poly – predicted to transform the multi-billion-dollar professional and recreational sports apparel and teamwear markets, suffering today from major limitations with mass customization of polyester

The four-day event is attended by some of the top designers, retailers, brands, fulfillers, and ecommerce players, in addition to global investors and press – and will include exclusive VIP experiences demonstrating the confluence of the design, technology, and fashion worlds. Together, these three elements are central to Kornit’s 4.0 strategy, bringing sustainable, on-demand fashion to the mainstream with end-to-end workflow solutions.

Kornit Fashion Week Tel Aviv 2022

Kornit Fashion Week features an immersive runway showcase produced by worldwide fashion icon, producer, director, and entrepreneur Motty Reif. The week follows successful Kornit events in 2021 across Los Angeles, New York, Milan, and Tel Aviv – displaying the creative freedom associated with sustainable, on-demand fashion fulfillment.

Attendees will experience runway events showcasing designer creativity across a broad array of collections. These fascinating collections were created in just a few weeks, unlike typical fashion and textile production processes that take over six months.

The event marks the most diverse and inclusive array of designers, models, and garments digitally printed on an unmatched number of materials. Collections highlight the liberation from inefficient, costly, and wasteful production processes, as well as long lead times and supply chain constraints. The power of on-demand production also drives creation of the most imaginative collections.

Industry-First Introductions

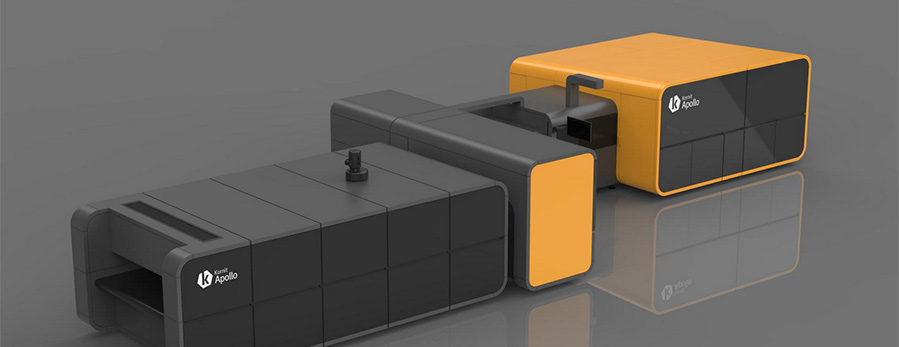

Looking behind the scenes at Kornit Fashion Week, attendees will witness Kornit’s disruptive mass production technology in action. Unveiled for the first time, the Kornit Apollo direct-to-garment (DTG) system addresses accelerated post-pandemic market trends for streamlined supply chains and production nearshoring.

Demonstrated at an exclusive VIP event, Kornit Apollo features the Company’s proven MAX technology offering the highest retail quality combined with full automation control and integrated smart curing processes, utilizing functionality from Lichtenau, Germany-based Tesoma (Kornit’s recently announced acquisition). The solution is the most comprehensive digital, single-step end-to-end system for nearshore short-and-medium-runs mass production and offers optimal TCO and highest output per operator. The result far surpasses performance of screen printing and analog techniques. With early customer engagements in the second half of 2022, the system will be available mid-2023.

According to a pre-COVID survey published by McKinsey & Co., a majority of US apparel executives projected that over 20% of their sourcing volumes would come from nearshore production by 2025, indicating a major shift to demand-focused apparel value chains. Based on post-COVID supply chain disruptions, dynamics of digitization, automation, lean inventory management, and sustainability, Kornit sees an acceleration of this trend and projects the shift will be much more significant in volume and speed, especially in the apparel categories that are relevant for the Company’s DTG solutions.

“These accelerating shifts to nearshore and short- and medium-run production, in addition to the breakthrough digital advancements we are introducing with Apollo, should allow Kornit to address significantly more of the annual global decorated apparel jobs, generating a multi-billion-dollar opportunity for our customers and partners,” said Ronen Samuel, Chief Executive Officer at Kornit Digital.

“The fashion and textile industry is at a critical inflection point,” added Samuel. “As the design, technology, and fashion worlds converge, there’s a tremendous opportunity now created. Kornit is writing the operating system for fashion – and today, we are introducing game-changing technology for mass production that will offer a powerful alternative to screen printing.”

“Producers and creators are increasingly shifting to nearshore and onshore production,” said Omer Kulka, Chief Marketing Officer at Kornit Digital. “Our upcoming Kornit Apollo solution comes at the right time for the industry and our customers. This allows both current and future customers to take advantage of these market trends, opens new markets for Kornit, and will drive new customer adoption. The Kornit Apollo technology directly addresses the industry needs, and we believe it will increase our market reach.”

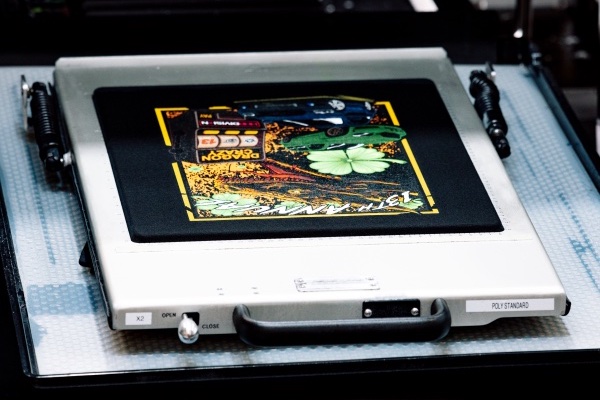

Also unveiled will be the distinctive Kornit Atlas MAX Poly DTG production system – the industry-first high-volume digital decoration solution for polyester and polyester-blended apparel. Approximately 16% of global t-shirt volume is estimated to be polyester, representing the second-largest segment of this category. As the fashion and sport apparel markets come together, a significant new opportunity for fashion on polyester is emerging. Kornit Atlas MAX Poly now creates new possibilities in an industry where black and greys are the norm. For the first time ever, the recreational sportswear, promotional, and sports brand market can capitalize on a wide range of colorful designs to inject new life into their apparel. This new quality standard was previously unattainable and is fully based on Kornit MAX technology.

The solution additionally incorporates Kornit’s XDi decorative applications, creating new styles for multiple effects and unlimited combinations such as threadless embroidery, high-density vinyl, screen transfer emulations, and 3D simulation. Kornit XDi powers virtually endless designs and creativity on polyester – introducing never-before-seen on-demand innovation for the recreational sportswear, promotional, and sports brand markets.

Available in the second quarter of 2022, this newest entry into the Kornit MAX portfolio removes barriers associated with polyester production, ensuring high quality and durability while setting benchmarks for creativity and productivity.

Continuing its mission to digitize the production floor, Kornit is additionally introducing the Company’s revolutionary ActiveLoad™ solution for automation. With selective availability in the second half of 2022, and commercially available in 2023, ActiveLoad automates the loading of garments on Kornit Atlas MAX systems to increase production by ~20%, maximize resources, and improve overall quality and consistency by reducing operator errors.

Physical and Virtual Worlds

Kornit enables customers to exchange supply chain headaches and materials waste for unsurpassed creativity and a frictionless pixel-to-parcel-to-doorstep production experience. Supported by the KornitXworkflow solution, customers have access to a scalable and modular ecosystem for on-demand decorated apparel and textiles. Supporting diverse supply chain models, the infrastructure-agnostic system enables on-demand, automated production, end-to-end from initial order to package delivery.

As virtual fashion becomes a reality, Kornit will continue to take this digital transformation to the next level – seamlessly connecting the physical and virtual worlds. At Kornit Fashion Week Tel Aviv, the Company will offer select demonstrations of this transformation – with even further use cases at upcoming events, including Kornit Fashion Week London in May 2022.

Samuel concluded, “As the fashion and textile industry begins to capitalize on the merging physical and virtual worlds, only Kornit allows customers to harness these changes, unleash creative freedom, and empower full self-expression with KornitX. We are committed to empowering customers to push the boundaries of their creativity. By connecting the virtual and physical, we power a world where almost anything is possible.”

To learn more about transforming your fashion and textile production operations, please read our latest blog post. To view a select assortment of vibrant fashion shows at Kornit Fashion Week Tel Aviv 2022, please visit livestreams located on our LinkedIn and Facebook pages. More photos and content can also be found on our full digital press kit.