#Digital Printing

New Mimaki printer launches the next (r)evolution in textile printing

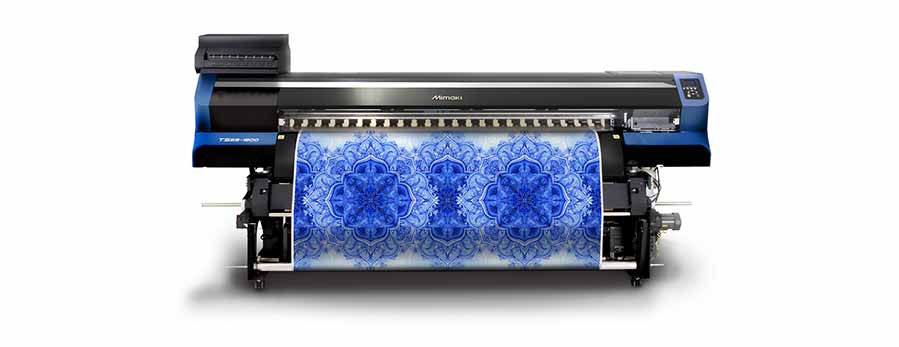

With the release of the TS55-1800, Mimaki delivers on making high-end digital textile printing features available to a much broader market. Now, textile professionals can effortlessly scale their operation with an affordable heat sublimation printer that meets the high quality and fast turnaround times demanded in the dynamic textile and apparel industry. The new model prints at a resolution of 480x600 dpi with a high ink density using one-pass printing at 140 sqm/h (1,506 sq.ft/h). In addition, the unique Mimaki Advanced Pass System (MAPS4) improves the quality of two-pass printing by eliminating banding. The TS55-1800 achieves all this with low running costs and the high-productivity and reliability that Mimaki products are known for.

“The TS55-1800 is a breakthrough digital textile printer, that will surely cause a stir in the market,” said Bert Benckhuysen, senior product manager at Mimaki Europe. “It has been designed from the ground up to deliver high quality, industry-leading productivity and an operational cost that will be hard to beat.”

Unattended printing

One of the key features of the TS55-1800 is the optional use of new Mini Jumbo Roll unit that can continuously feed 2,500 linear meters of heat transfer paper to the printer. This enables customers to substitute the use of Small Plotter Rolls with Mini Jumbo Rolls, which can save them over 20% in print media cost. Furthermore, Mini Jumbo Rolls of Mimaki Vision Jet-X transfer paper, supplied by Neenah Coldenhove, will be offered as package deal with the TS55-1800.

The 2,500 m1 Mini Jumbo Rolls are the ideal way to upgrade to high-volume unattended textile printing. In addition, the printer is fitted with the unique Mimaki Nozzle Check and Recovery System and 10-liter ink tanks, which ensure failsafe continuous operation for extended operational periods, such as overnight-unattended printing.

Higher profitability

Mimaki offers its customers a high return on investment with the TS55-1800 that will be sold at a very competitive price-point.

“The Mimaki TS55-1800 offers the best specifications for the best price,” said Benckhuysen “According to our projections, textile professionals can reduce their operational cost by using this new printer and double their annual profit. This is truly revolutionary, and we believe it will make a huge contribution to the ongoing analogue-to-digital transformation underway in the industry.”

The new printer will be on first public display at three upcoming trade shows:

- Sign Istanbul, 20-23 September, Mimaki Eurasia Stand E20, Hall 12

- C!Print Madrid, 25-27 September, Digidelta Stands C50 and A49, Hall Planta Baja

- Viscom Italia, 18-20 October, Mimaki Bompan Textile Stand G20/G26/E23/E27, Hall 8

More details about Mimaki products, including its full line of printers, inks and cutting machines, can be found at http://www.mimakieurope.com.