#Composites

A critical product for the aerospace industry by Fabric Development Inc and Textile Products Inc

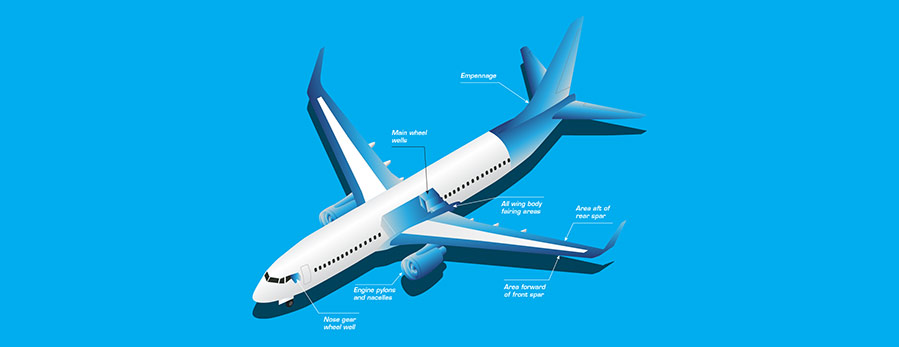

According to statistics, a plane can be struck by lightning once a year on average, making lightning protection highly essential in aircrafts for the safety of various components including generators, fuel valves, electrically controlled power feeders, and electrical distribution systems. However, unlike their metal counterparts, composite structures do not conduct away the electrical currents and electromagnetic forces generated by lightning strikes. As the use of composites has expanded during the past three decades, a wide range of lightning strike protection fiber has been adopted for aerospace industry.

Having an extensive experience in working with high performance fibers, reinforcement leader Kordsa’s US based companies, Fabric Development Inc., and Textile Products Inc., manufactures lightning strike protection and EMI shielding fabrics with a wide range of fiber and construction options. Both companies also offer custom designed lighting strike protection and EMI shielding fabrics engineered to meet specific customers' needs for weight and conductivity including both conductive and structural requirements.

The Lightning Strike Protection and EMI shielding fabric is an integrated metallic wire, or better a fiber and wire hybrid. It reduces the energy density of the lightning flowing onto the composite structure. Less energy density means less damage. Therefore, this fabric provides greater impact resistance while improving the life cycle of the part.

Lightning Strike Protection and EMI shielding fabrics provide weight advantage compared to alternate approaches as the structural fibers and conductive wires are interwoven as one fabric and can be produced with multiple fiber systems such as carbon, glass, and aramid along with multiple conductive wires such as copper, aluminum, bronze, nickel and monel. Wires are chosen to meet a required conductivity. The fabric can be prepregged using standard equipment. Also, it is easier to mold in comparison to expanded metal and features exceptional cutting and handleability during kitting or lay-up, and is practical to combine into the surface ply of a composite layup resulting in a superior surface finish. It serves dual purposes as structural layer and conductive surface layer and is used for lightning strike protection and EMI shielding applications such as medical equipment, electronics, wind energy and consumer goods.

Fabric Development Inc. and Textile Products Inc. are US based Kordsa companies, a global player of tire, construction reinforcement and composites technologies market. Expanding its competencies with its investments in the composite field, Kordsa acquired both companies in 2018.